Vision Inspection

Military Testing System Leaves No Room for Error

Military Testing System Leaves No Room for Error

Challenge: Find a more accurate and controlled way of conducting high power microwave susceptibility testing at the Directed Energy technology office at the Naval Surface Warfare Center in Dahlgren, VA.

IAS Corp. Solution: Prior to contacting IAS Corp., high power microwave susceptibility tests were watched by human eye and manually logged by pen and paper leaving plenty of room for error. IAS Corp. created a vision system that increased accuracy and freed up time for scientists to work on other projects while testing is in progress.

For this project the existing reverberation chamber was fitted with a custom designed vision pod featuring a copper ring with conductive glass over the lens of a CCD camera. A standard PC with IAS Corp. vision software was used to collect data, and a custom user interface program was written to further simplify system setup and data output. This system can be setup to test any device that will fit in the chamber. It is not affected by ultra high frequencies, will detect any change in status of the test subject, and provides accurate results for all tests.

The cost for testing the old way was $34,000.00 per test cycle. The cost for testing new way is $3,750.00 per test cycle, plus manpower can be used to work on other projects while testing.

Click here to download Power Point presentation ![]()

IAS Corp. Services Delivered:

- Vision Inspection

- Custom Software Application

- Engineering R&D Services

- Automation & Efficiency

A Forward Thinking Solution to a Backwards Installation Problem

A Forward Thinking Solution to a Backwards Installation Problem

Challenge: Gambro Healthcare in Hampton, VA had an existing machine that worked well with one exception; periodically it would install a valve backwards. They needed a solution that would ensure no bad parts were shipped 100% of the time.

IAS Corp. Solution: IAS Corp. provided a Diaphragm Valve Inspection System to inspect each pump and ensure that the diaphragm valve is oriented in the correct flow direction. The system features two high-speed high-resolution cameras and custom IAS Corp. / Advanced Automation Group vision software. Pumps that have valves installed correctly are allowed to continue to the next station. Pumps that have incorrectly installed valves or suspect valves are rejected. This system is used for quality control on 100% of the valves installed and has remained in use for more than 10 years.

IAS Corp. Services Delivered

- Vision Inspection

- Custom Software application

- Engineering R&D Services

- Automation & Efficiency

Sophisticated System Makes Process fully Automatic & Robotic

Sophisticated System Makes Process fully Automatic & Robotic

Challenge: Streamline testing of fuel injector components to increase productivity.

IAS Corp. Solution: For Greystone of Virginia / Induplate, LLC in Toano, VA IAS Corp. provided a sophisticated inspection system on Camco rotary indexing tables to inspect Robert Bosch fuel injector components. The system is fully automatic and utilizes robot arms to load parts into the machine where they are inspected with eight high speed high resolution cameras, laser micrometers, and x-ray machines. Defects can be detected down to 0.5 micron. All parts are removed from machine with robot arms. Passing parts are placed in a "passed inspection" tray. Defective or suspect parts are sorted into trays depending on the defect allowing for trending and fine tuning of plating lines. This system is responsible for increasing production output and reducing the amount of scrap parts made.

IAS Corp. Services Delivered:

- Vision Inspection

- Custom Software application

- Engineering R&D Services

- Automation & Efficiency

Assembly Line & Machine

Custom Built Stations Improve Productivity for Automotive Parts Manufacturer

Custom Built Stations Improve Productivity for Automotive Parts Manufacturer

Challenge: Federal-Mogul needed an automated stand-alone system to quickly test and aim foglamps for multiple Chrysler, Dodge, and Jeep vehicles such as Concord, Cirrus, Liberty, Caravan, Durango, Dakota, Ram, and others. The system must be easy to use and convert from one type of vehicle to the next quickly. This includes domestic and foreign housing/ bulb types.

IAS Corp. Solution: The Foglamp Aiming Station, created by IAS Corp is semi-automatic. An operator places a lamp on the fixture. A connector is automatically inserted into the bulb and it is illuminated. A camera looks at the bulbs "hot spot" while a laser looks at the lamp housing. If the assembly is within adjustment range and the bulb was not bent during insertion into the housing, a screwdriver will come down and adjust it to specification. Once adjusted the system will “voice announce” the test results and await the next assembly to be tested. All test data is collected to track manufacturing and provide statistics.

IAS Corp. Services Delivered

- Vision Inspection

- Custom Software application

- Engineering R&D Services

- Automation & Efficiency

Test Fixtures

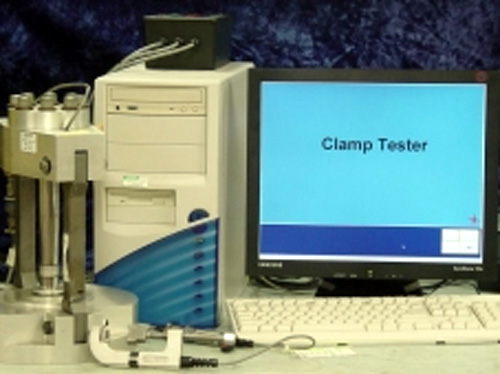

New System Gauges Clamp Viability before Major Failure

New System Gauges Clamp Viability before Major Failure

Challenge: Strain Gauge Clamps for Motor Operated Valves are tested before each use to make sure they are within specification. Testing was time consuming, as it was done by hand and allowed too much room for human error. Client requested a faster and more accurate method of testing.New System Gauges Clamp Viability before Major Failure

IAS Corp. Solution: The CaliClamp test system verifies strain gauge clamps are within manufacturer specification. Easy to use, an operator attaches the strain gauge clamp to a standard test fixture. Data for the clamp is entered into the program. An electric hydraulic pump is used to cycle the stem/clamp 30 times and a signature is taken of the clamp for each test. Results are recorded into a database and inserted into a formula provided by the clamp manufacturer. A report for each clamp is generated to determine if the its specifications are within tolerance. This system was provided to be turn-key or as an update to existing stem test stand.

IAS Corp. Services Delivered:

- Custom Software application

- Engineering R&D Services

- Automation & Efficiency

Strong Bond Created with Adhesive Strength Tester

Strong Bond Created with Adhesive Strength Tester

Challenge: Client needed a portable instrument that could accurately Strong Bond Created with Adhesive Strength Testerperform pull force testing.

IAS Corp. Solution: Our Adhesive Strength Tester is a compact desktop instrument used for bond testing in the adhesive industry. Measuring the amount of force required to separate two pieces of substrate, this system features custom software that displays all test information and provides spreadsheet or graph output files. Optional LCD is available for standalone use. CLICK HERE for more information on the Tack-N-Bond Portable Pull Force Assessment System.

IAS Services Delivered:

- Adhesives

- Test Fixtures

- Engineering R&D Services

Detecting Missing Mobile Phone Parts

Detecting Missing Mobile Phone Parts

Challenge: Motorola needed a quick way to detect missing parts during mobile phone production. The solution must be fast, easy to understand for any language, and upwardly compatible.

IAS Corp. Solution: We provided fixtures to detect part presence and make sure they had been installed correctly during the mobile phone manufacturing process. If parts are missing or improperly inserted, a buzzer will sound and a LED will illuminate indicating which part is suspect. Our fixtures not only make this testing fast, they are easily upgraded to keep up with phone revisions, saving manufacturers time and money.

IAS Corp. also offers design and construction of prototypes. Once approved, we provide all the files required for manufacturing allowing the customer to control production overseas.

IAS Corp. Services Delivered:

- Test Fixtures

- Custom Software application

- Engineering R&D Services

Gasket Size / Shape Verification for Auto Industry Now Automatic

Gasket Size / Shape Verification for Auto Industry Now Automatic

Challenge: ITW/Southland, a tier 1 supplier of automotive parts for Chrysler needed a method of measuring gaskets dimensions and determining if all parts are present.

IAS Corp. Solution: We designed and constructed a station that could test gaskets of many sizes/shapes and indicate those that were passed/failed parts. Overall shape is measured with the use of CCD cameras and part presence is determined with contact probes. The test time is less than 1 second. If part passes, it is marked with a dot and a green light illuminates. If part fails, a buzzer will sound and a red lamp will illuminate. All data is recorded and tracked for manufacturing trending.

IAS Corp. Services Delivered:

- Test Fixtures

- Custom Software application

- Engineering R&D Services

IAS Corp. has completed projects for healthcare manufacturers, US military, automotive parts manufacturers, adhesive companies and many others in need of quality controls and inspection services, including:

- Naval Surface Warfare Center Dahlgren

- Gambro Healthcare

- Greystone of Virginia / Induplate, LLC

- Federal Mogul

- Black & Decker

- Motorolla

- Smithfield Foods

- Valeo Automotive

- National Starch & Chemical

- National Adhesives

- Electrolux

Whether you have a small part that needs testing for viability or an entire facility that needs to run more efficiently, contact IAS Corp. today to see how our capabilities in quality control and inspection services work do for you.

Celebrating 26 Years!

Celebrating 26 Years!