IAS Grommet Inspection System revolutionizes how rubber grommets are tested

IAS Grommet Inspection System revolutionizes how rubber grommets are tested

Challenge: ITW/Southland, a tier 1 automotive parts supplier for Chrysler, contacted IAS Corp to provide a system to test rubber grommets for defects after several previous attempts with off the shelf vision inspection systems failed.custom grommet inspection System

IAS Corp Solution: IAS Corp developed and built a grommet inspection system that utilizes multiple cameras, custom IAS Corp vision software, Bully Boy lighting, and advanced motion control. This proprietary system inspects and sorts more than 3600 grommets per hour, and can be switched over from one of 6 grommet types to another in less than 5 minutes. Each grommet is checked for dimensional accuracy while being inspected for defects such as short shots, flashing issues, defects in the surface, and even cuts in the rubber surface. This is not easy to do with dense black rubber parts. The system is fully automatic. An operator loads parts in a bowl feeder. After inspection, passing parts are counted and dumped into a shipping container. Failed parts are sorted out into different bins depending on the defect to help in manufacturing trending.

IAS Corp Services Delivered:

- System design and construction

- C++ Programming

- System setup / installation

- Training and support

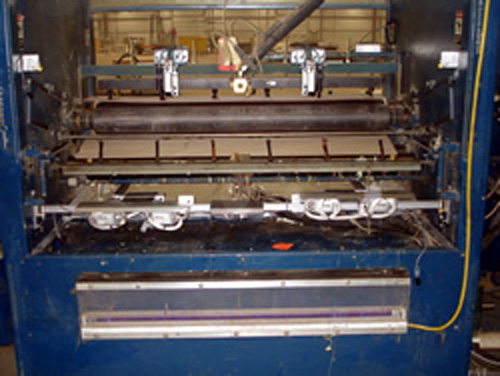

Superior Monitoring System for Black Brothers Hot Melt Roll Coater

Superior Monitoring System for Black Brothers Hot Melt Roll Coater

Challenge: Design a system that can accurately track adhesive usage, determine coat weight, and monitor application temperature to ensure substrate bonding and reduce the amount of waste in the manufacturing of Recreational Vehicle / Motor Home walls.

IAS Corp Solution: IAS Corp. technicians took an existing Black Bros roll coater and installed our patented universal monitoring system. For this application we created custom non-contact sensors that can accurately determine the coat weight of the adhesive during the coating process and interfaced them to our system. The end product allows for super fast setup and adjustment of the machine. This system had an ROI of less than 6 months.

IAS Corp. Services Delivered:

- System design and construction

- C++ Programming

- System setup / installation

- Training and support

IAS Creates Solution for Pre-Applied Re-Melt System Built in 1/4 of the Time

IAS Creates Solution for Pre-Applied Re-Melt System Built in 1/4 of the Time

Challenge: IAS Corp was called in by National Adhesives to finish a project for which the original development company could not provide positive results after 5 months of work. The existing system was useable but plagued with problems, and a better solution was needed prior to delivery to the end customer in only 5 weeks.

IAS Corp Solution: For this project our team constructed a duplicate production line in our shop to test different ways to perform the task at hand. We put in the up-front testing that is required for a good end result and developed a system that was installed on the end-customer’s line and refined to perform the task without reducing production speed. IAS engineers and technicians accomplished in 5 weeks, something the other firm could not do in 5 months, and the system is still in use today, 4 years later.

IAS Corp. Services Delivered:

- Research

- System setup / installation

- Training and support

Envelope Quality Station - EQ2100: Same USPS Precision at a Fraction of the Cost

Envelope Quality Station - EQ2100: Same USPS Precision at a Fraction of the Cost

Challenge: National Adhesives asked IAS Corp. to design and build a bench top system that could test envelopes with the same precision as the system used by the USPS (Merlin) at a fraction of the cost.

IAS Corp Solution: Contracted by National Adhesives / National Starch and Chemical in Bridgewater, NJ, IAS engineers developed the Envelope Quality Station - EQ2100. This bench top system is capable of testing envelopes with the same precision as the US Postal Service Merlin (Mail Evaluation Readability Lookup Instrument), a tool used by the US Postal Service to verify first class mail, standard mail, and periodicals against the standards set in the Domestic Mail Manual.

The system we provided checks the adhesive bond that holds an envelope together by measuring the force needed to burst the envelope. It takes multiple measurements of the adhesive that has been applied across the flap that is used for sealing, inspects the cellophane window for defects such as rips, wrinkles, or cuts and measures the print for proper placement and saturation of color graphics if present.

In addition to ensuring envelopes will pass Merlin examination, test results are used to make certain that the correct amount of adhesive has been used to construct the envelope. These systems are proprietary to National Adhesives and are used to help them maintain a top ranking position in the tough adhesives market.

IAS Corp. Services Delivered:

- System design and construction

- C++ Programming

- System setup / installation

- Training and support

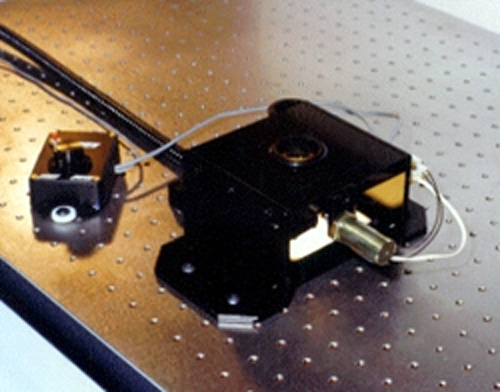

Optical Counter offers Bio-Medical Solution for Counting Moving, Microscopic organisms

Optical Counter offers Bio-Medical Solution for Counting Moving, Microscopic organisms

Challenge: Provide a system that is capable of counting moving daphnia (small, planktonic crustaceans, between 0.2 and 5 mm in length, commonly known as water fleas) in water samples.

IAS Corp Solution: This optical counter created by IAS Corp., is an intelligent vision system used in the bio-medical manufacturing industry. An optical counter “excites” specimens that cannot be seen without magnification that have been poured into a clear cup and placed into a fixture. While this is taking place, a high speed, high resolution camera is used to observe and count the number of living specimens versus the non-living specimens. This project included custom optically clear sample cups / trays, and automated handling for unattended incubation to viewing area.

IAS Corp. Services Delivered:

- System design and construction

- C++ Programming

- System setup / installation

- Training and support

IAS Corp has completed projects for adhesive companies, bio-medical and manufacturing companies, machine shops, and many others in need of engineering research & development, including:

- ITW/Southland

- National Adhesives

- National Starch & Chemical

- Eagle Aviation Technologies

- IDEC Aerospace

- Gambro Healthcare

- Electric Motor and Contracting

- Modern Machine and Tool

- Omega Engineering

Whether you have a small part that needs testing for viability or an entire facility that needs to run more efficiently, contact IAS Corp. today to see how our capabilities in engineering research & development can work for you.

Celebrating 26 Years!

Celebrating 26 Years!